The Way to the SKEDD Technology

The solid press-fit technology presses a rectangular metal pin into the metallized hole of a circuit board with a defined force (Fig. 1). This results in a powerful, gas-tight electrical connection.

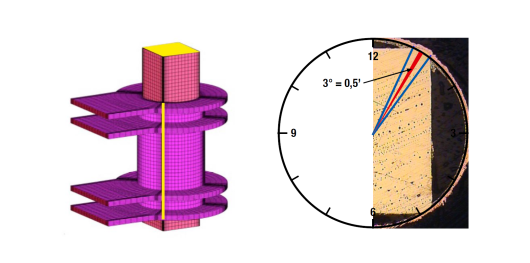

The electrical transfer resistance plays a crucial role in the quality of this connection. The lower the electrical transfer resistance, the better the connection, because a resistance generates a voltage drop and, therefore, heat. In order to keep the electrical transfer resistance low, the current must have a discharge surface which is at least comparable to the entrance surface (discharge surface ≥ entrance surface) – irrespective the correct selection of materials. In order to meet this condition and to avoid a bottleneck, the connection angle of a corner of the contact pin must typically measure at least 3°. As the figure 2 shows, the real press-fit connection possesses many reserves. This is a reason for the excellent functionality of the press-fit connections. The SKEDD technology uses exactly this connection principle, "to contact over the edges directly into the sleeve".

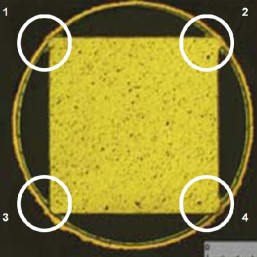

It is important, as known from the press-fit technology, that a reliable 4-edge connection with a sufficiently high contact pressure is realized. So, the requirement for the design of the SKEDD fork is to realize a contact normal force which is high enough to ensure an electrically safe connection. At the same time, however, the contact normal force must permit a reversible plugging by hand even in the case of higher-pole plug-in connectors.