SKEDD Contact – Construction

Basically, there are three requirements on the design of the SKEDD stamped contacts to enable vibration-proof connection and reversible plugging into the metallized hole of the printed circuit board:

- To ensure that the connector remains physically insertable, the insertion forces should not be too high, so that even connectors with large numbers of pins can be inserted by hand.

- On the other hand, the insertion force must be sufficient to ensure that sufficiently low contact resistance is obtained and to establisch vibration-proof connection.

- Additionally, the contact material and contact geometry should interact in such a way that no plastic deformation of the contact occurs.

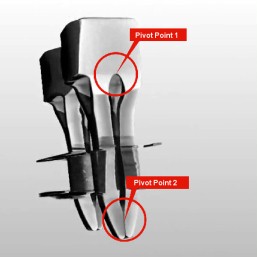

These requirements are met by the SKEDD contact with the illustrated design with two pivot points.

The first pivot is in the apex where the two arms join and determines the forces that occur when the connector is inserted into the PCB. In the plugging process, the fork is open and the elasticity is provided by the apex area. This area is designed precisely in a way that the insertion forces remain moderate, yet sufficient normal contact forces are present.

The second pivot point is located at the lower end of the SKEDD contact. The contact is designed in the way that the fork is exactly closed in the inserted state. Mechanically this means that the behavior of the spring, e.g. its stiffness, suddenly changes. Now the spring is significantly more robust in protecting against shock and vibration movements. This is important, in turn, to ensure that no interruption of contact occurs due to mechanical stress.

The SKEDD contact is also designed in the way that the material does not plastically deform because of the plugging process. The contact remains in the elastic state and enables reversible insertion and removal.